Wax Casting

The process of casting a metal object from a mold made from an original wax model is known as lost wax casting. A plaster-like material is used to make the mold, which is poured over the wax model and allowed to set.

Contact us today for more information.

Leading-Edge Manufacturing Technology

We use the most advanced manufacturing technology and materials from cutting-edge industry leaders

What is Wax Casting?

The Basics of Wax Casting

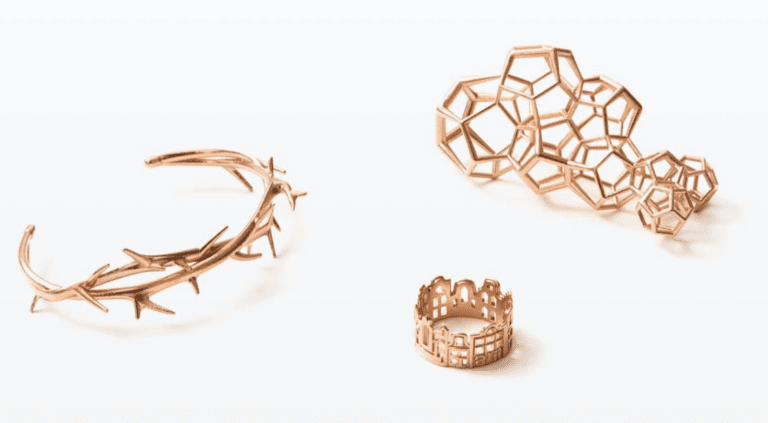

By casting an original model or pattern, wax casting can be used to create anything from simple to complex objects in a variety of metals (like gold, silver, brass, or bronze). Although it is one of the oldest known methods for forming metal, it is still widely used to make jewelry, art, and dental work. In engineering and manufacturing, investment casting, its industrial form, is a common method for producing precision metal parts. The lost-wax casting process has traditionally been associated with artisanal handicraft. However, creators can now simplify the workflow, save time, and lower costs by using digital design and 3D printing to reshape the process for the 21st century.

How Wax Casting Works

Metal casting has many facets and typically requires numerous, careful steps. At RP Group, the process of creating wax patterns for plaster molds is accompanied by cutting-edge technology like 3D printing. As the initial wax is melted and drained, sprues are added to allow metal to flow through, which explains the term "lost wax casting."

The plaster is removed from the mold after the metal cools and solidifies. After the metal product is separated, post-processing begins. This could involve polishing the metal with tumbling or, if necessary, plating; For instance, gold or rhodium plating is an option for brass.

Benefits of Wax Casting

Thin walls, intricate shapes, delicate floral forms, multi-working procedures, difficult-to-machine materials, near net shapes, and the merging of multiple components into a single unit are all possible outcomes of wax casting. Material wastage and mass production can be avoided with this process.

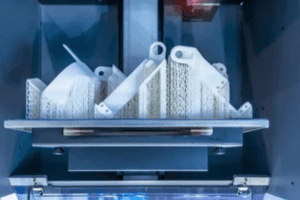

3D printing processes and materials available at RP Group

Selective Laser Sintering [SLS]

High level of accuracy, relatively cheap raw material, and high temperature resistance make it perfect for a wide range of structural engineering applications.

Materials available: Nylon PA12, Nylon PA12 with glass beads

PolyJet Printing

PolyJet is a 3D printing technology similar to inkjet document printing, but instead of jetting drops of ink onto paper, PolyJet 3D printers jet layers of liquid photopolymer onto a build tray and instantly cure them with UV light

Materials available: Vero, VeroClear, ABS-Like, Rubber-Like

Stereolithography [SLA]

Stereolithography (SLA) creates parts in a layer-by-layer fashion by using photochemical processes whereby light causes chemical monomers to link together to form polymers.

Materials available: ABS natural and ABS clear stimulants.

Binder Jetting

3D printing technologies create a smooth wax pattern, which is used to create casting molds to produce precious metal parts.

Materials available: Stainless Steel 17-4PH, Stainless Steel 316L, Steel and Sandstone.

HP Multi Jet Fusion [MJF]

Multi Jet Fusion can produce functional nylon prototypes and end-use production parts in as little as one day.

Materials available: Nylon PA12, Nylon PA12 with glass beads and polypropylene (PP)

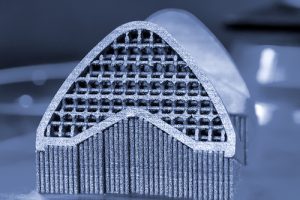

Laser Powder Bed Fusion Metal (LPBF-M)

Selective Laser Melting (SLM) process uses a laser to scan and selectively melt the metal powder particles, bonding them together and building a part layer-by-layer.

Material available: Aluminum.

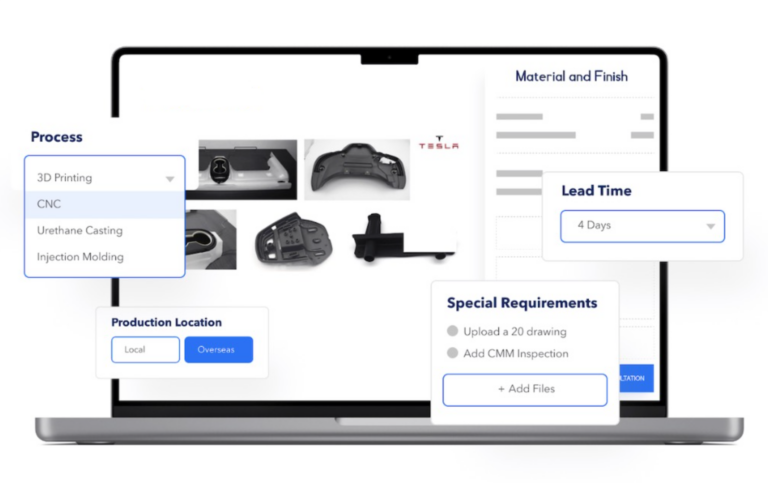

Online instant quoting

Prototyping is all about speed so using our online portal, customers can upload their data and get instant feedback on costs and place an order with less hassles.

- Select from a wide range of materials.

- Compare pricing options instantly

- Manage quotes and orders in our online portal

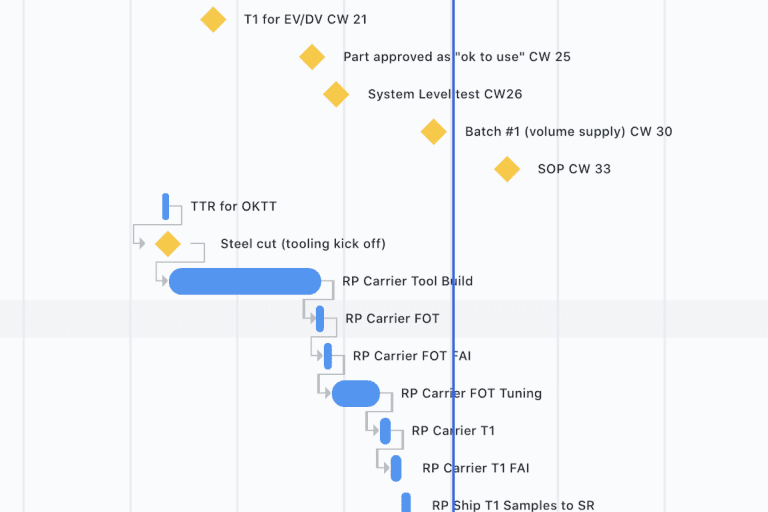

Project management portal and transparent traceability

Keep track of all of your projects on-demand for updates, status and tracking your shipments. The online portal provides a great way to manage complex projects and make seamless communication.

- Track the progress of your project

- Photos and videos of your parts before they ship

- Quality inspection reports online