What is Slot Milling?

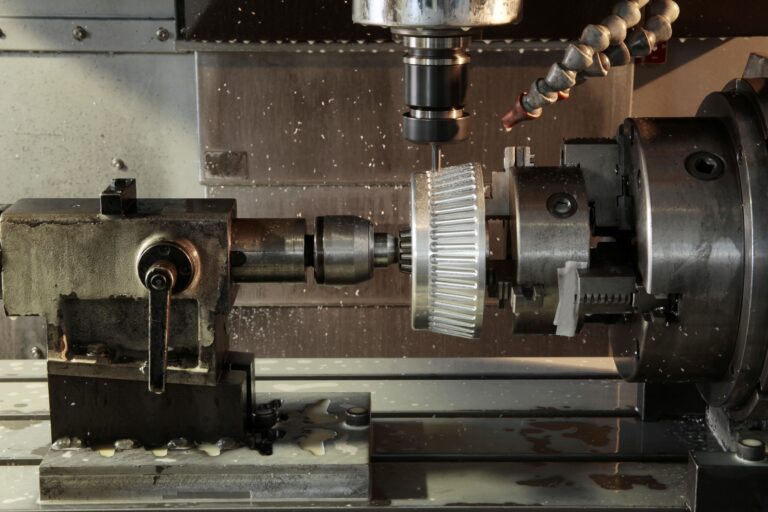

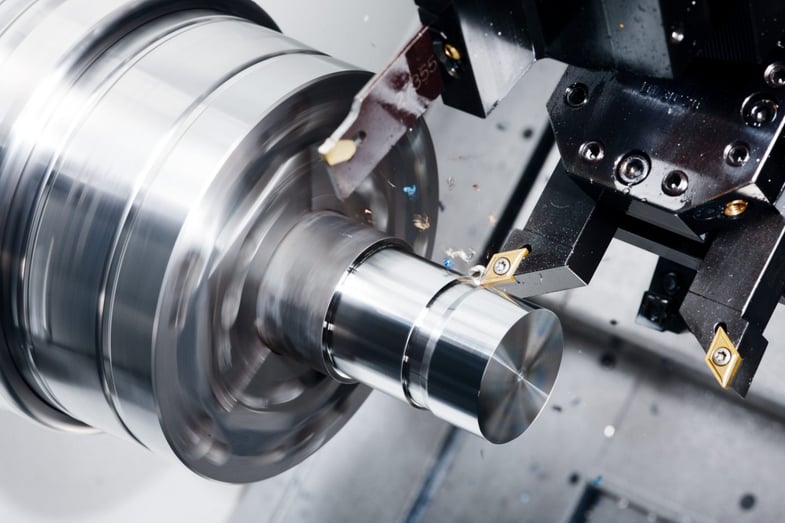

In slot milling, a rotating tool with multiple cutting edges is used to craft grooves in a workpiece. This technique creates components with accurate slots, keyways, or channels. Slot milling stands out as a flexible and accurate machining technology.

Slot Milling Uses

How Does Slot Milling Work?

How Does Slot Milling Differ From Other Milling Techniques?

The main factor that sets slot milling apart from other types of milling is how the tool moves in relation to the workpiece. In slot milling, the tool moves along its own axis, unlike face milling, where the cutter moves across the workpiece, or peripheral milling, which cuts along the edges. This axial movement in slot milling allows for creating channels or slots in the workpiece. The way the tool moves affects what each milling technique is good at. Peripheral milling is great for shaping, face milling makes flat surfaces, and slot milling, with its axial movement, is perfect for making precise grooves or slots. Knowing these differences helps machinists pick the right technique for specific jobs, taking into account things like material properties, surface finish needs, and how efficiently they want to machine.

What are the advantages of slot milling?

Advantages of slot milling include:

- It enables the creation of deeper slots or pockets compared to end milling.

- Slot milling simplifies the process of creating inner and outer profiles, offering an advantage over traditional milling machines that require frequent spindle realignment. Slot milling addresses these challenges by allowing simplified machining without constant spindle adjustments, enhancing accuracy, and streamlining production processes.

- Slot milling cutters are particularly effective in machining solid-jaw mandrels, guide bars, and flat metal parts. These cutters facilitate precise shaping and slot creation by efficiently removing material in a rotational motion. Their versatility makes them essential in various metalworking applications, delivering accuracy and efficiency in crafting intricate component

What are the disadvantages of slot milling?

Disadvantages of slot milling include:

- High vibrations may occur, particularly when cutting deep slots or working with challenging-to-cut materials.

- The continuous cutting action in slot milling produces elevated radial forces, reducing stability, especially in deep cuts.

- The cutting process can generate rapid heat buildup in both the tool and workpiece, impacting tool longevity and the quality of the machined part.

What Are the Types of Slot Milling Cutters?

2. End Milling Cutter

3. Side Milling Cutter

4. Gang Milling Cutter

5. T-Slot Cutter

6. Woodruff Key Slot Cutter

Choosing the right slot milling cutter

Tips for successful slot milling

Conclusion

To learn more about slot milling, reach out to a representative from RP Group.

RP Group offers a diverse array of manufacturing capabilities, encompassing machining and additional value-added services tailored to meet your prototyping and production requirements. Explore our website for more information or to submit a request for a complimentary quote with RP Group.