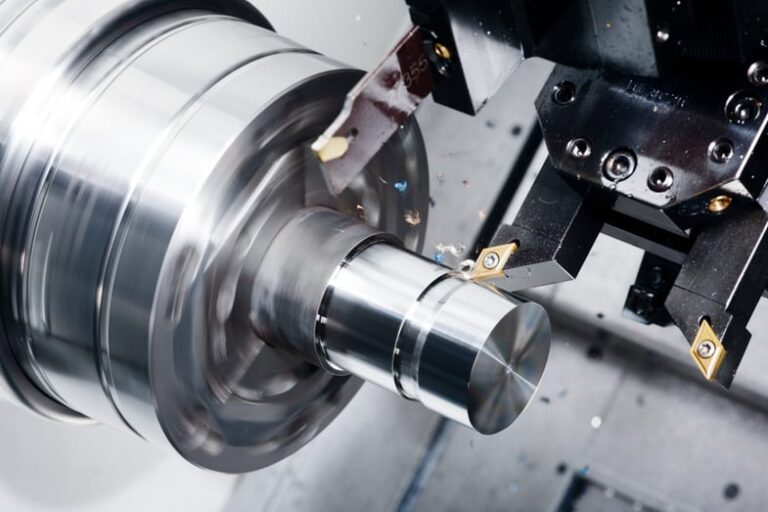

1. Unparalleled Precision:

CNC machining stands out for its unmatched precision. Computer-controlled systems ensure that every cut, every drill, and every movement is executed with microscopic accuracy, resulting in parts and products that meet the tightest tolerances.

2. Versatility Across Materials:

Whether you’re working with metals, plastics, composites, or even exotic materials, CNC machining offers exceptional versatility. The ability to handle a wide range of materials makes it an ideal choice for diverse industries such as aerospace, automotive, and medical.

3. Complex Geometries Made Easy:

Traditional machining methods may struggle with intricate and complex designs, but CNC machining excels in bringing intricate geometries to life. The computer-driven precision allows for the creation of intricate shapes and detailed components that would be challenging or impossible with other methods.

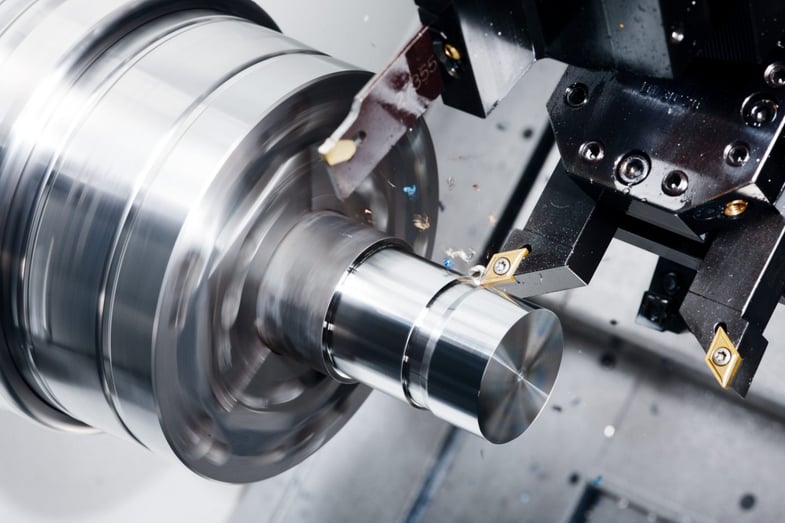

4. Consistency in Production:

Consistency is a hallmark of CNC machining. Once a program is set, the machine executes it repeatedly with the same precision, ensuring that each piece matches the specified design. This level of consistency is crucial for large-scale production runs where uniformity is paramount.

5. Rapid Prototyping:

Time is of the essence in product development, and CNC machining shines in the realm of rapid prototyping. Design changes can be quickly implemented in the computer program, and the machine adapts seamlessly, allowing for faster iteration and refinement of prototypes.

6. Enhanced Efficiency:

CNC machines operate 24/7, significantly reducing production times compared to manual machining. The automated nature of CNC machining minimizes downtime and increases overall efficiency in the production process.

7. Cost-Effective for Mass Production:

While CNC machining can be costlier for small production runs or prototypes, its cost-effectiveness becomes apparent in large-scale manufacturing. The efficiency, speed, and consistency of CNC machining contribute to lower per-unit costs in high-volume production scenarios.

8. Minimized Human Error:

Human error is a common concern in manufacturing, but CNC machining minimizes this risk. With precise computer programming, the likelihood of mistakes is greatly reduced, resulting in higher-quality products and less material wastage.

9. Improved Safety Standards:

CNC machining enhances workplace safety by reducing the need for manual labor in the manufacturing process. Operators can control the machine from a distance, minimizing exposure to potential hazards associated with traditional machining methods.

10. Adaptability for Customization:

In a world where customization is increasingly important, CNC machining offers adaptability to unique specifications. Whether it’s a one-of-a-kind prototype or a specialized component, CNC machines can be programmed to produce customized outputs efficiently.

Conclusion:

In conclusion, the adoption of CNC machining is a strategic move for industries seeking precision, efficiency, and versatility in manufacturing. As technology continues to advance, the role of CNC machining is poised to expand, driving innovation and setting new standards for the production landscape. Whether you’re a small-scale operation or a large industrial player, the benefits of CNC machining make it a compelling choice for achieving manufacturing excellence.