Stereolithography (SLA)

Utilizing RP Group's SLA 3D printing service, you can procure high-performing components for rapid prototyping and production. We supply a wide range of industrial and prototyping resins and can print parts in as little as one day.

Leading-Edge Manufacturing Technology

We use the most advanced manufacturing technology and materials from cutting-edge industry leaders

Stereolithography (SLA) 3D Printing Service

The Basics of Stereolithography (SLA)

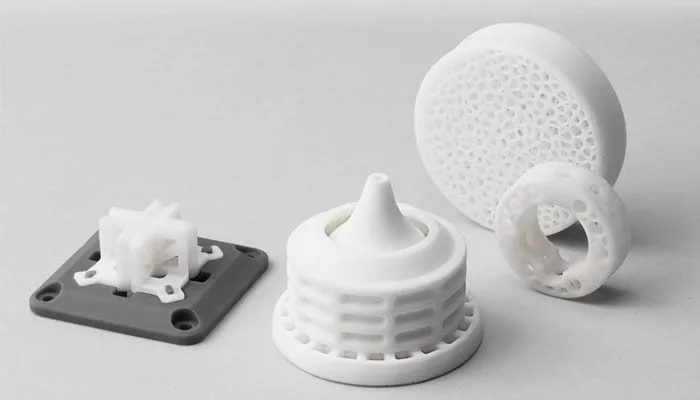

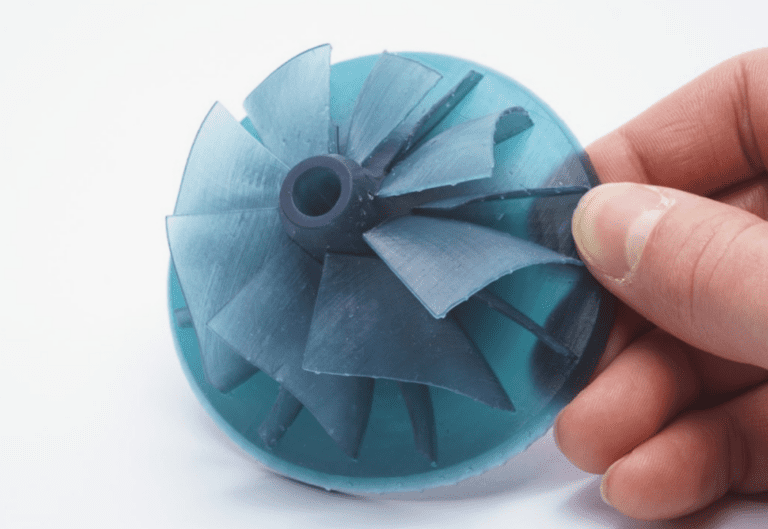

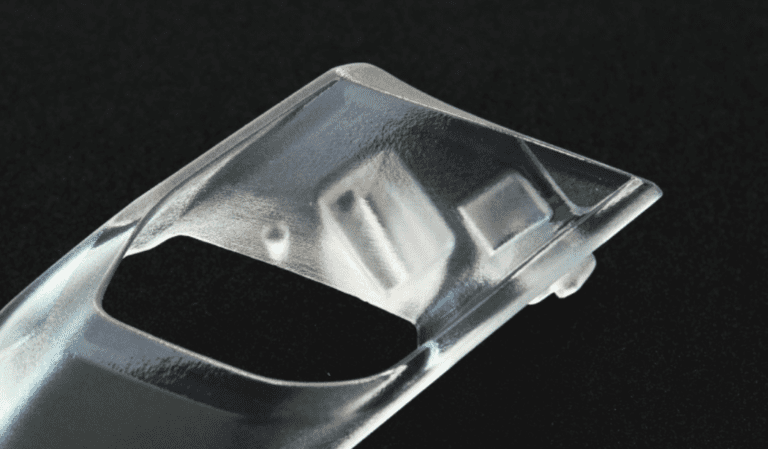

Resin 3D printing, also known as stereolithography (SLA), is a type of 3D printing that produces parts with high resolution and accuracy, fine details, and smooth surface finishes. SLA technology, which is a member of the vat photopolymerization printing family, makes custom parts by using photosensitive thermoset polymers. For large-scale production and rapid prototyping, we use materials from Formlabs and 3D Systems.

How SLA Printing Works

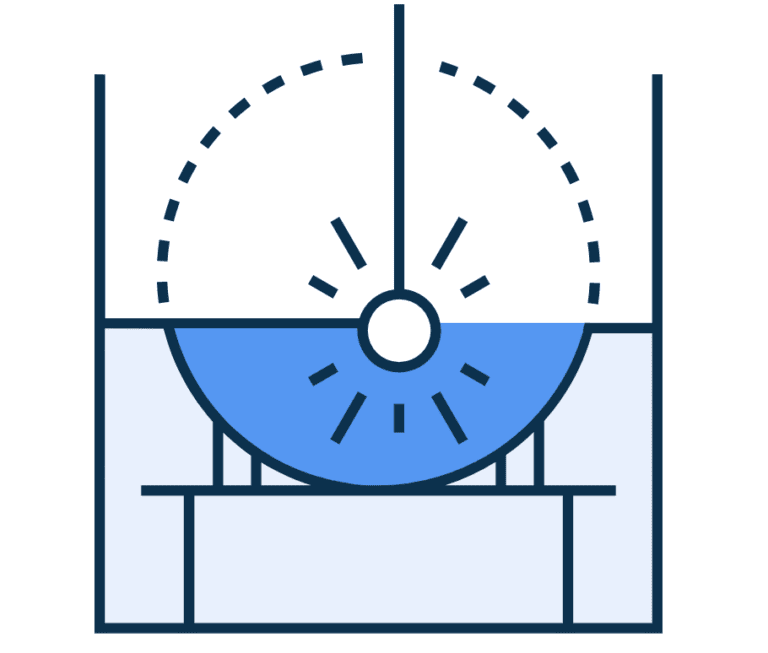

A method of additive manufacturing known as stereolithography makes use of ultraviolet (UV) light applied to a vat of liquid photopolymer resin to selectively solidify part features and construct the part layer by layer. The resin is selectively cured and solidified by the UV light throughout the entire vat to match the CAD file's design. After the print is finished, support structures are manually removed during the pre-build setup process. After that, the components undergo a final post-cure in an ultraviolet light oven before being washed in a solvent solution to get rid of any uncured resin.

Benefits of Stereolithography (SLA)

For 3D-printed models with precise features and a smooth surface finish, SLA is the best option. RP Group's stereolithography 3D printing service can print larger parts and products with a build area of up to 29 inches, and it offers standard and high-resolution options for fine detail parts. Before moving on to injection molding services, an SLA 3D print is frequently used for final fit checks due to its ability to produce complex features with good mechanical properties.

RP Group's manufacturing partner network also enables us to offer a wider range of materials than other 3D printing companies do. For example, we offer a wide variety of materials under the Accura and Somos brands.

3D printing processes and materials available at RP Group

Selective Laser Sintering [SLS]

High level of accuracy, relatively cheap raw material, and high temperature resistance make it perfect for a wide range of structural engineering applications.

Materials available: Nylon PA12, Nylon PA12 with glass beads

PolyJet Printing

PolyJet is a 3D printing technology similar to inkjet document printing, but instead of jetting drops of ink onto paper, PolyJet 3D printers jet layers of liquid photopolymer onto a build tray and instantly cure them with UV light

Materials available: Vero, VeroClear, ABS-Like, Rubber-Like

HP Multi Jet Fusion [MJF]

Multi Jet Fusion can produce functional nylon prototypes and end-use production parts in as little as one day.

Materials available: Nylon PA12, Nylon PA12 with glass beads and polypropylene (PP)

Binder Jetting

In binder jetting, a binder is selectively deposited onto the powder bed which bonds these areas together. This forms a solid part one layer at a time.

Materials available: Stainless Steel 17-4PH, Stainless Steel 316L, Steel and Sandstone.

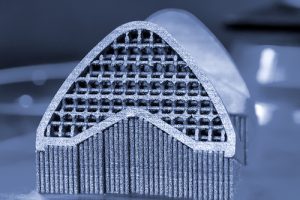

Laser Powder Bed Fusion Metal (LPBF-M)

Selective Laser Melting (SLM) process uses a laser to scan and selectively melt the metal powder particles, bonding them together and building a part layer-by-layer.

Materials available: Aluminum

Wax Casting

3D printing technologies create a smooth wax pattern, which is used to create casting molds to produce precious metal parts. Materials available: Brass, bronze, copper, gold, platinum, silver

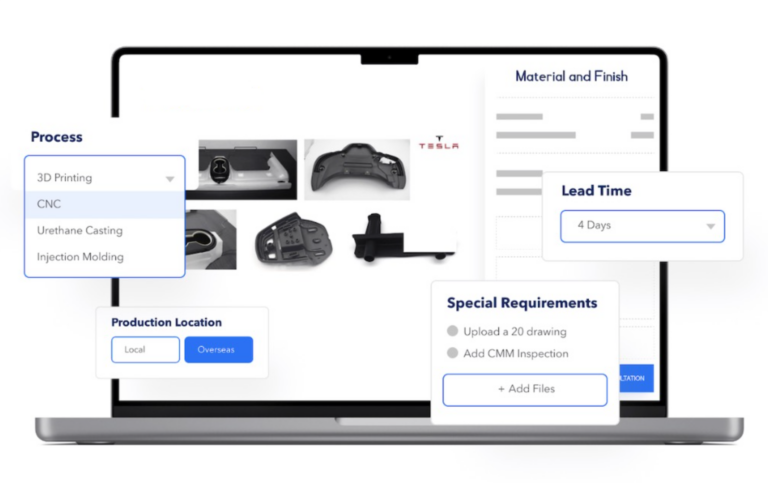

Online instant quoting

Prototyping is all about speed so using our online portal, customers can upload their data and get instant feedback on costs and place an order with less hassles.

- Select from a wide range of materials.

- Compare pricing options instantly

- Manage quotes and orders in our online portal

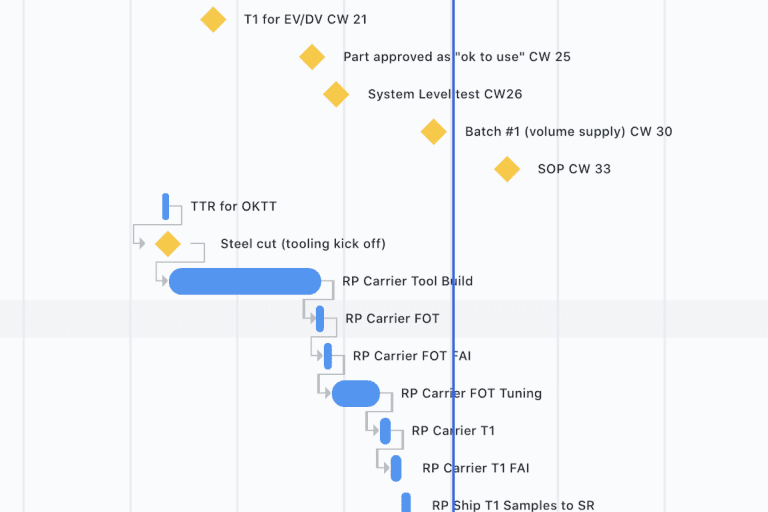

Project management portal and transparent traceability

Keep track of all of your projects on-demand for updates, status and tracking your shipments. The online portal provides a great way to manage complex projects and make seamless communication.

- Track the progress of your project

- Photos and videos of your parts before they ship

- Quality inspection reports online