CNC Milling

- Instant online quote & DFM

- Parts in as fast as 2 days

- Tight tolerances

- Your IP is safe with us

Certifications

ISO 9001: 2015

IATF 16949:2016

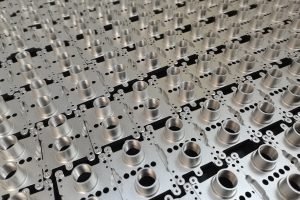

40,000+

Machined parts each month

50+

CNC machines

100+

Plastic and metal materials

What is CNC Milling?

The Basics of CNC Milling

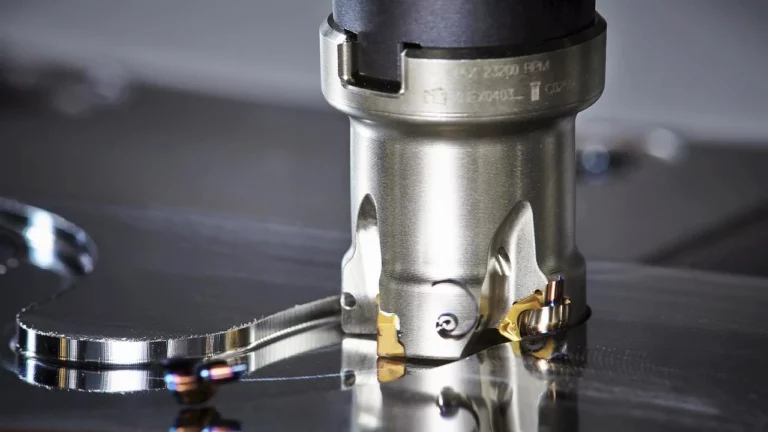

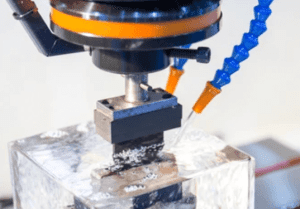

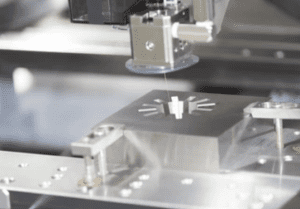

CNC mills are automated cutting machines that leverage a rotating spindle-head to eradicate excess material. These machines come in an assortment of sizes and axis configurations. While typically employed to cut harder metals, they are capable of working with workpiece materials spanning from plastic and aluminum to stainless steel and titanium.

How CNC Milling Works

CNC mills are particularly adept at precision cutting of harder materials. Similar to other CNC machines, a CNC mill is directed by G-Code, which is produced via CAM software. The G-Code commands the machine regarding tool head movement, tool speed, cutting depth, workpiece positioning, and other factors related to speed, feed rate, and coordination. The G-Code's complexity is determined by the number of axes that the milling machine possesses. While mills can also profile cut softer materials, it is not as cost-effective as CNC routers for that purpose. The primary difference between these machines is that a CNC router maintains a stationary workpiece while the router cutting head is guided around it, whereas a CNC mill can move both the tool head and the workpiece.

All CNC Machining Services

CNC Milling

3, 4 and 5-axis machining of plastic and metal parts. Machine up to 66" in size*

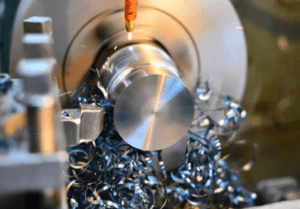

CNC Turning

Tight tolerances and finishing capabilities, as fast as 2 days.

Sinker EDM

Production quality parts without the tooling investment.

Wire Cutting EDM

Add anodizing or powder coating to your item for a variety of finishes.

CNC Service Applications

Low Volume Production

RP Group offers full production-quality parts in volumes ranging from a single piece to a few thousand pieces.

Appearance Prototypes

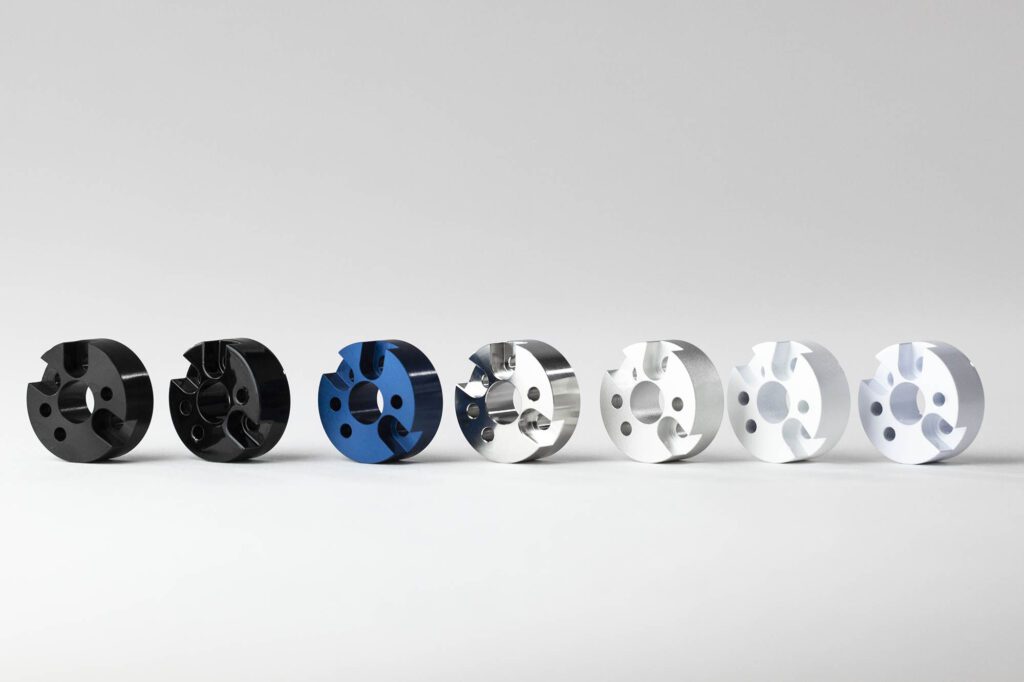

We take pride in producing the finest appearance models and prototypes with very high detail in any material you want.

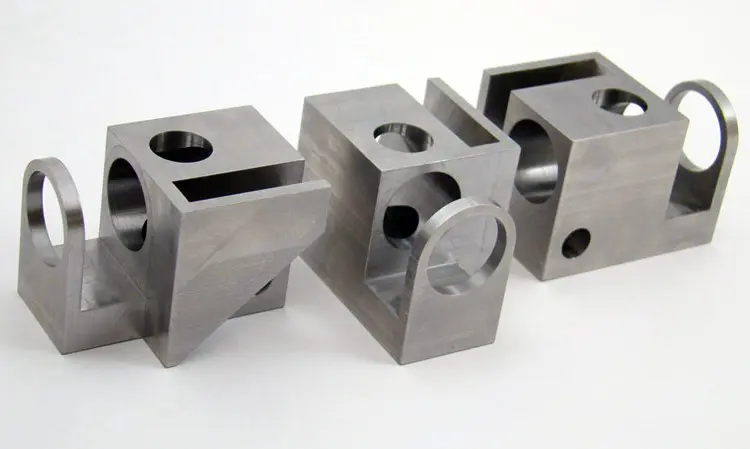

Fixtures and Gauges

We engineer fixtures and gauges to your specifications and may offer recommendations based on our in depth understanding of Geometric Dimension and Tolerancing (GD&T).

CNC Machining Materials

Metals

- Aluminum

- Brass

- Copper

- Stainless Steel

- Steel Alloy

- Magnesium

- Titanium

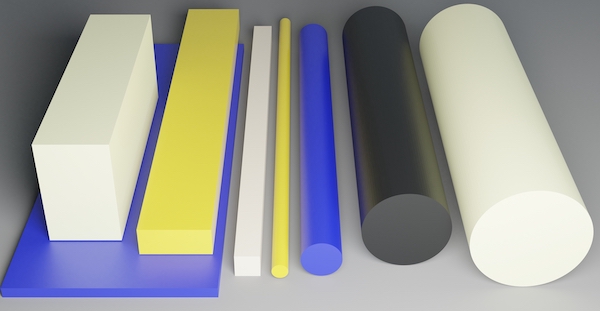

Plastics

- ABS

- Acetal

- CPVC

- HDPE

- LDPE

- Nylon

- PEEK

- PEI

- PET

- PMMA

- Polycarbonate

- Polypropylene

- PPSU

- PS

- PSU

- PTFE

- PVC

Finishing Options

At RP Group we can generate instant quotes for 10+ surface finishes. We can help you select the right finishes for your applications.

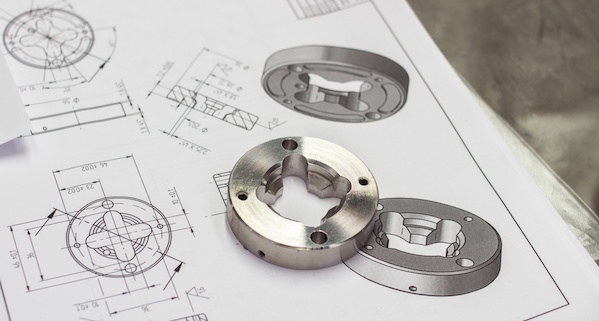

CNC Precision Machining Tolerances

At RP Group, we use ISO 2768 standards for CNC machining.

The length of parts that RP Group accepts depends on the machining process, with some processes accepting parts up to 48 inches in length. For larger parts, it is recommended to get in touch with RP Group's team.

It should be noted that the tolerances indicated are minimums in an optimal scenario and looser tolerances may be necessary based on the process, material selection, or part geometry.

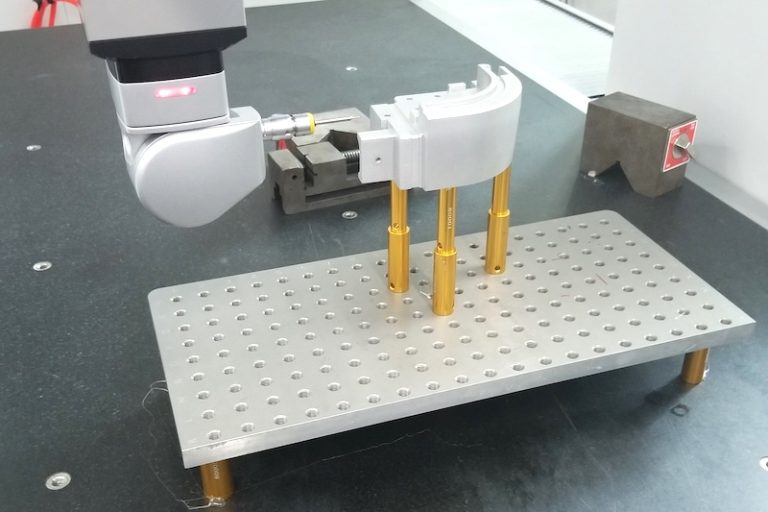

Metrology

At all four of our RP Group manufacturing locations, we have a fully equipped metrology department to ensure your part's quality compliance. Experienced engineers in fixture and gauge design from GD&T.

- Programmable

- 3D Scanning

- Fixture and gauge manufacture

Why choose RP Group for CNC Machining?

Design for Manufacture

Our experienced engineers will analyse your design and provide feedback on manufacturability and look for opportunities to reduce cost.

Communication

We are always quick to respond to questions via email, phone, web meeting or chat to ensure your project turn around is as fast as possible.

Quality Reports

All projects where 2D drawings are provided come with a dimension report before parts are shipped. CMM reports can be produced on demand at no additional charge.

Transparent Progress Reports

We provide progress and tracking information through our customer portal. Videos and photos of the parts can be confirmed before parts are shipped out.

Time to Market

We have a infinite capacity via our vetted supply chain outside our own in house capabilities so we have the flexibility to manage all projects large and small.

Full Service Manufacturing

We can offer a wide range of materials, processes, finishes and sub-components to make us your one-stop supplier for your whole project.

CNC Milling FAQs

Our usual suggestion is to use a minimum wall thickness of 0.5mm for metals and 1mm for plastics. Nevertheless, these values are mainly influenced by the part's size, hence as the part size increases, the recommended minimum wall thickness should also increase. It's worth noting that lower wall thickness values can still be feasible. These recommendations act as limits to mitigate the likelihood of warpage

To ensure precise machining of a part, it is necessary to program CNC machines with offsets for the tool's diameter and length that will be used to cut the part. With accurate knowledge of the tool offsets, a machinist can determine the exact starting point for the machining process.

The CNC milling process involves a rotating tool that carves away excess material from a stationary workpiece.

CNC turning uses a rotating workpiece, typically used to make cylindrical parts.

The most commonly used materials in CNC milling are metals, such as aluminum, brass or steel and plastics such as ABS, acrylic, polycarbonate, and polypropylene.