Metal Binder Jetting 3D Printing Service

Discover the technology of binder jetting, and start making the most of metal 3D printing for your next projects.

Contact us today.

Leading-Edge Manufacturing Technology

We use the most advanced manufacturing technology and materials from cutting-edge industry leaders

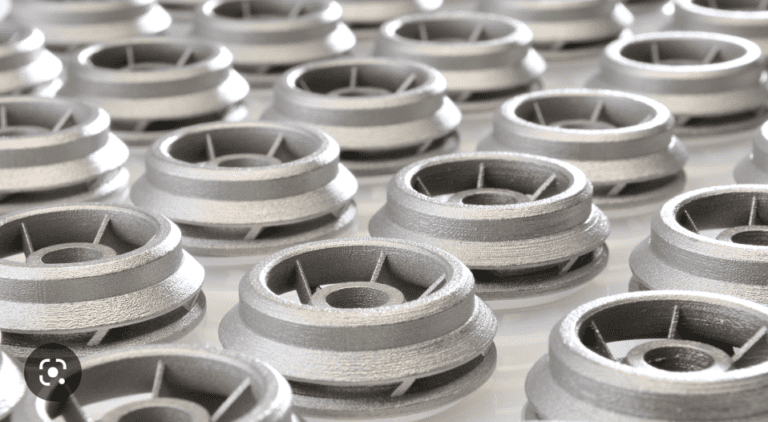

What is Metal Binder Jetting?

The Basics of Metal Binder Jetting

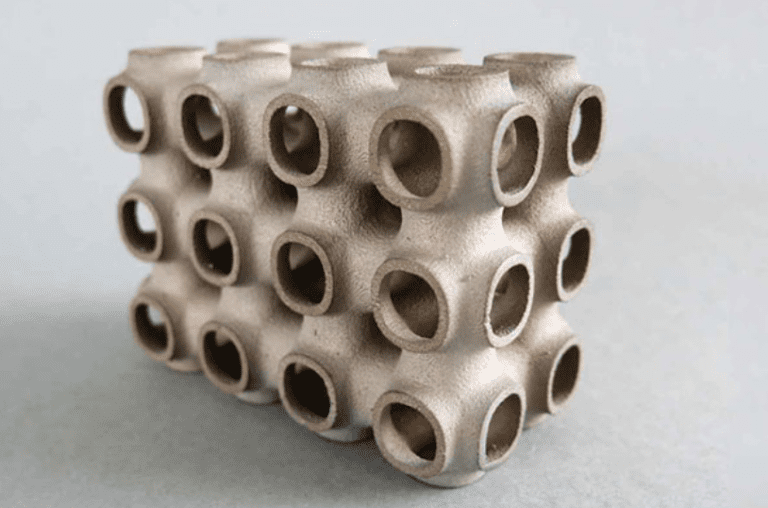

Binder jetting is an additive manufacturing process. An industrial printhead selectively deposits a liquid binding agent onto a thin layer of powder particles such as foundry sand, ceramics, metal or composites in order to build high-value and one-of-a-kind parts and tooling.

How Metal Binder Jetting Works

Metal binder jetting is a multi-step technology for additive manufacturing used to builds metal parts. Firstly, binder jet machines fuse layers of metal powder together using a binding agent. Once bound, the resulting shape is called a green part and is left to cure. The cured form is then put into a furnace to sinter or be infiltrated with bronze.

There is no need for post-processing because binder jet parts are supported on all sides by powder that has not been used. It is important to keep in mind that because the majority of parts made with binder jets must go through a furnace stage, they may shrink, become slightly porous, or lose fine details. Binder jet components should be designed by engineers in accordance with DFM principles.

Benefits of Metal Binder Jetting

Binder jetting has a number of advantages over traditional metal injection molding and other 3D printing methods. Printheads typically operate at a faster rate than lasers or electron beams, so the technology excels in terms of speed and resolution.

3D printing processes and materials available at RP Group

Selective Laser Sintering [SLS]

High level of accuracy, relatively cheap raw material, and high temperature resistance make it perfect for a wide range of structural engineering applications.

Materials available: Nylon PA12, Nylon PA12 with glass beads

PolyJet Printing

PolyJet is a 3D printing technology similar to inkjet document printing, but instead of jetting drops of ink onto paper, PolyJet 3D printers jet layers of liquid photopolymer onto a build tray and instantly cure them with UV light

Materials available: Vero, VeroClear, ABS-Like, Rubber-Like

Stereolithography [SLA]

Stereolithography (SLA) creates parts in a layer-by-layer fashion by using photochemical processes whereby light causes chemical monomers to link together to form polymers.

Materials available: ABS natural and ABS clear stimulants.

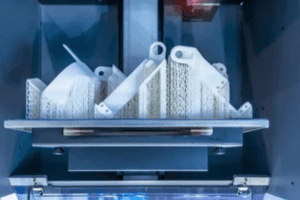

Laser Powder Bed Fusion Metal (LPBF-M)

Selective Laser Melting (SLM) process uses a laser to scan and selectively melt the metal powder particles, bonding them together and building a part layer-by-layer.

Materials Available: Aluminum

Wax Casting

3D printing technologies create a smooth wax pattern, which is used to create casting molds to produce precious metal parts. Materials available: Brass, bronze, copper, gold, platinum, silver

HP Multi Jet Fusion [MJF]

Multi Jet Fusion can produce functional nylon prototypes and end-use production parts in as little as one day.

Materials available: Nylon PA12, Nylon PA12 with glass beads and polypropylene (PP)

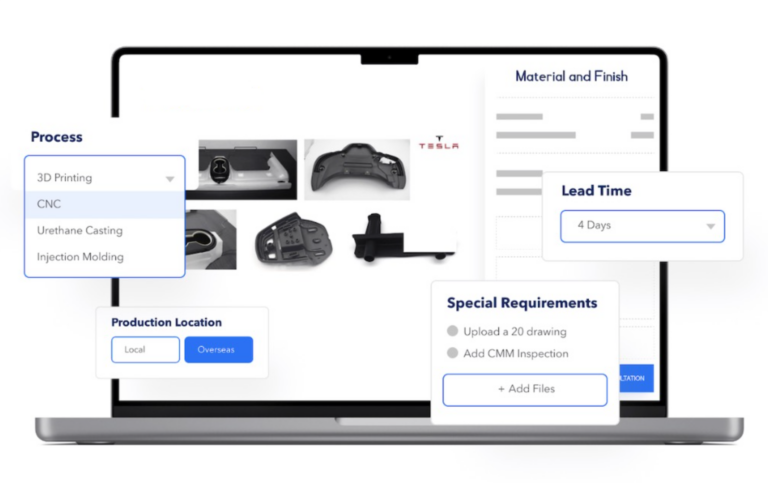

Online instant quoting

Prototyping is all about speed so using our online portal, customers can upload their data and get instant feedback on costs and place an order with less hassles.

- Select from a wide range of materials.

- Compare pricing options instantly

- Manage quotes and orders in our online portal

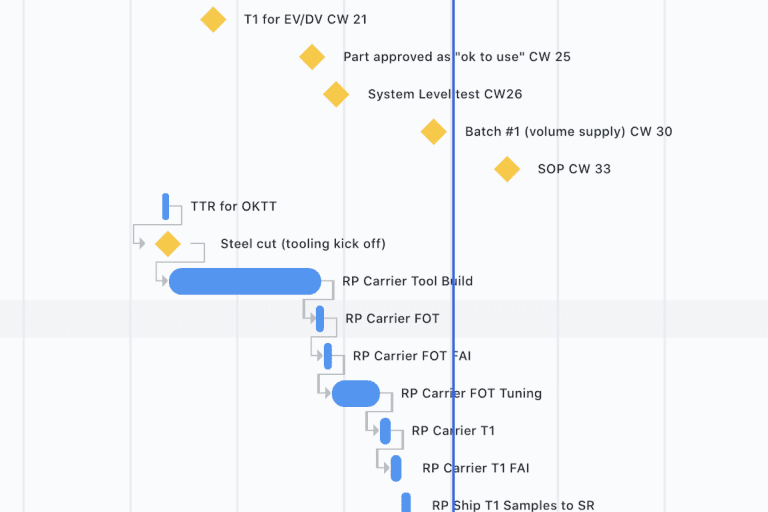

Project management portal and transparent traceability

Keep track of all of your projects on-demand for updates, status and tracking your shipments. The online portal provides a great way to manage complex projects and make seamless communication.

- Track the progress of your project

- Photos and videos of your parts before they ship

- Quality inspection reports online