The Importance of Color Consistency

1. Brand Identity and Recognition

Consistent color in your plastic components is crucial for maintaining brand identity. Whether it’s the vibrant hue of a consumer product or the specific shade of a medical device, color consistency ensures instant recognition and trust in your brand.

2. Quality Assurance

Color discrepancies can be indicative of variations in material composition or processing conditions. Achieving uniform color across a production run is a key indicator of a well-controlled and stable manufacturing process, reinforcing the overall quality of the product.

3. Consumer Perception

In industries where aesthetics matter, such as consumer goods or automotive design, the perceived quality of a product is often tied to its visual appeal. Color consistency contributes significantly to positive consumer perceptions and satisfaction.

Factors Influencing Color Consistency

1. Material Selection

The choice of raw materials plays a pivotal role in color consistency. Working closely with material suppliers and conducting thorough testing ensures that the selected materials meet color specifications and withstand the injection molding process without compromising hue.

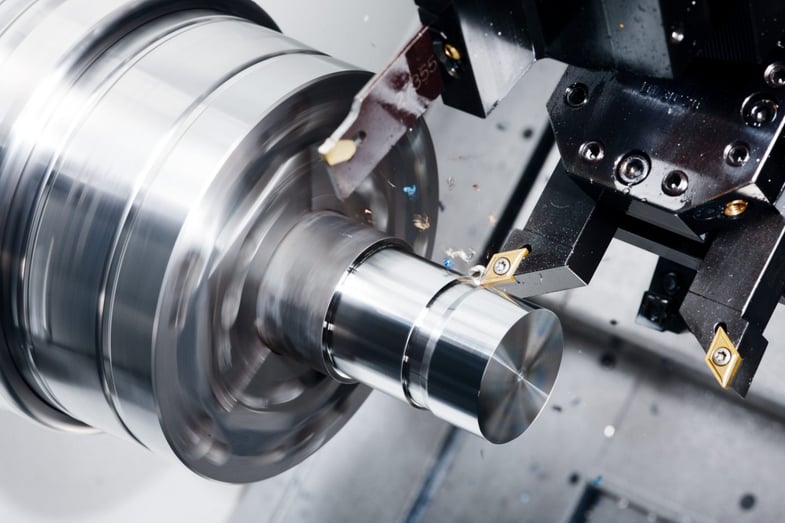

2. Process Control

3. Tooling and Equipment Maintenance

The condition of molds and equipment used in the injection molding process can influence color outcomes. Regular maintenance and inspection of molds help prevent issues like contamination or wear that could compromise color consistency.

Best Practices for Achieving Color Consistency

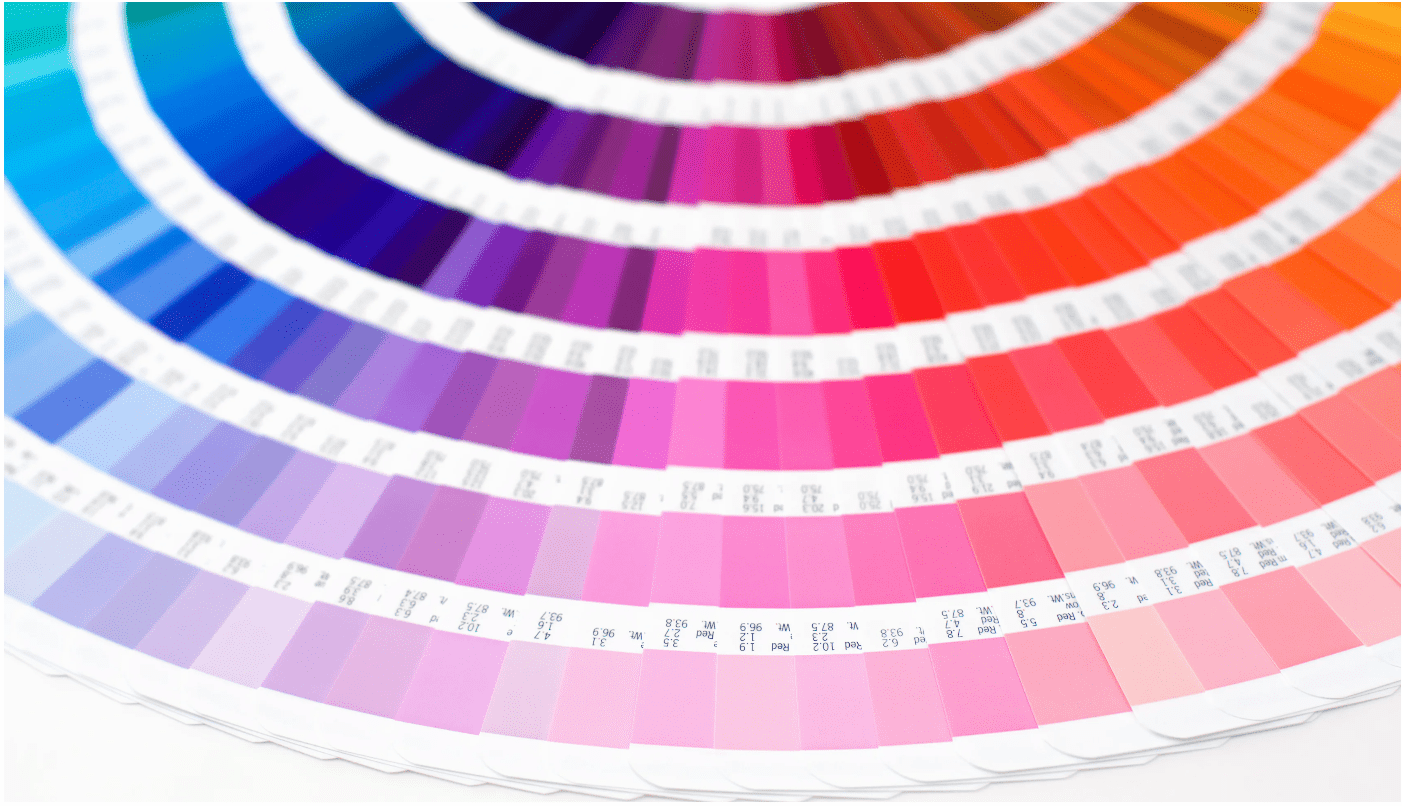

1. Color Marching Services

Utilize color matching services offered by experienced manufacturers. These services involve precise formulation of color pigments to achieve the desired hue, enabling manufacturers to reproduce consistent colors across production runs.

2. Testing and Validation

Conduct thorough testing and validation processes to ensure that color specifications are met. This includes color measurement devices, sample testing, and visual inspections to confirm that the final products align with the intended color standards.